How is Stainless Steel Sheet Produced?

1. Raw Material Selection: The raw materials required for stainless steel production are usually obtained from a mixture of iron ore, nickel, chromium and other alloys. These raw materials are melted in blast furnaces and turned into alloy steel.

2. Casting and Forming: Stainless steel is cast and shaped, usually into cast blocks or slabs. These slabs are cut to the appropriate dimensions for further processing.

3. Hot Rolling: The formed stainless steel sheets are subjected to the hot rolling process. In this process, stainless steel sheets are rolled at high temperature and brought to the desired thickness and size.

4. Cold Rolling: Hot rolled stainless steel sheets are subjected to cold rolling process. In this process, stainless steel sheets are cold rolled to obtain more precise thicknesses and surface smoothness.

5. Cutting and Forming: The processed sheet is cut and shaped to the desired dimensions. At this stage, it is ensured that the stainless steel sheet is shaped in accordance with its end use.

6. Final Processes: The produced stainless steel sheets are subjected to final controls and checked for compliance with quality standards. Then, they are packaged according to customer demands and prepared for shipment.

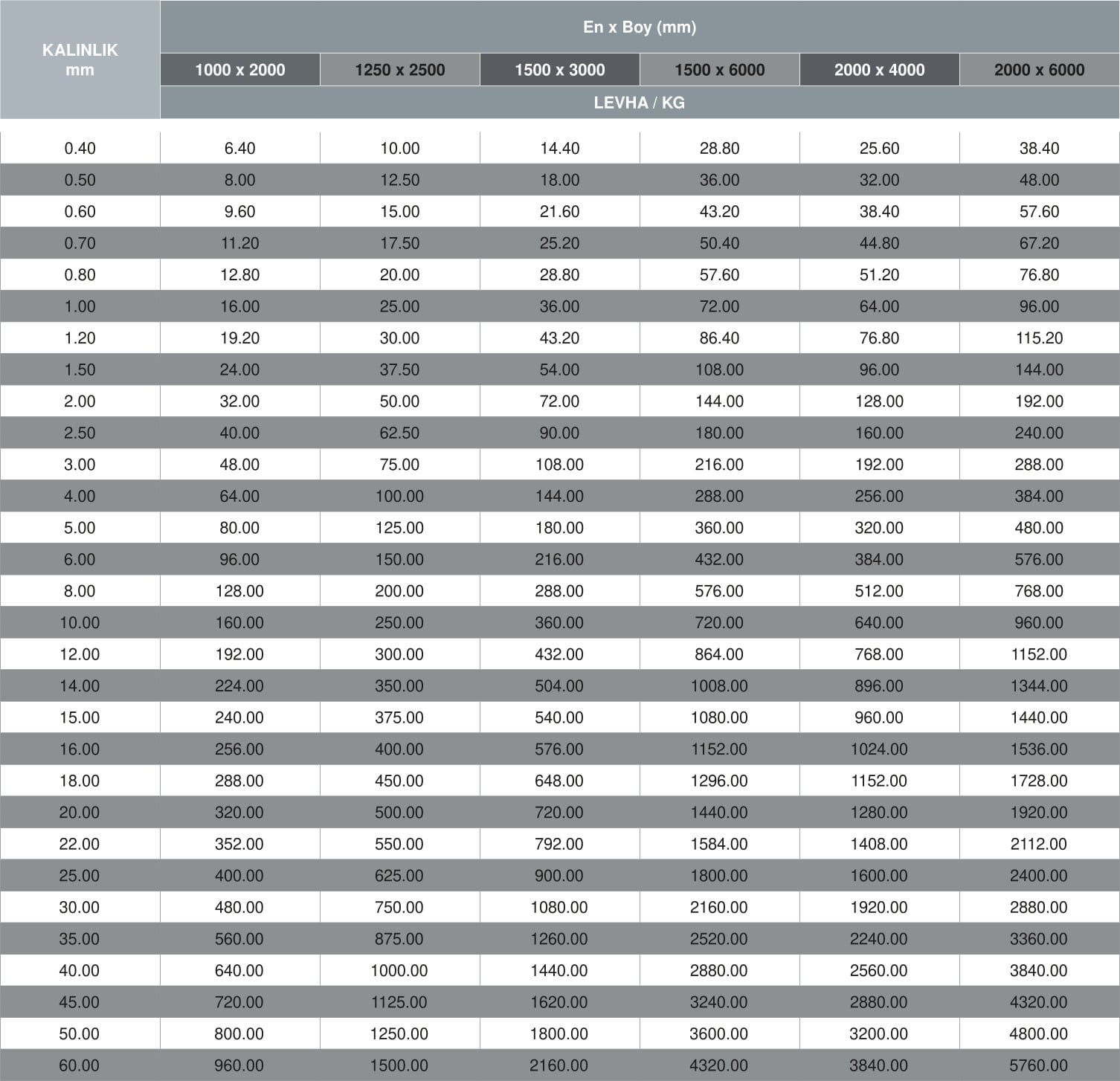

For more information and pricing information about stainless steel sheets, you can view our catalog or contact us.